ASSEMBLY LINE AUTOMATION

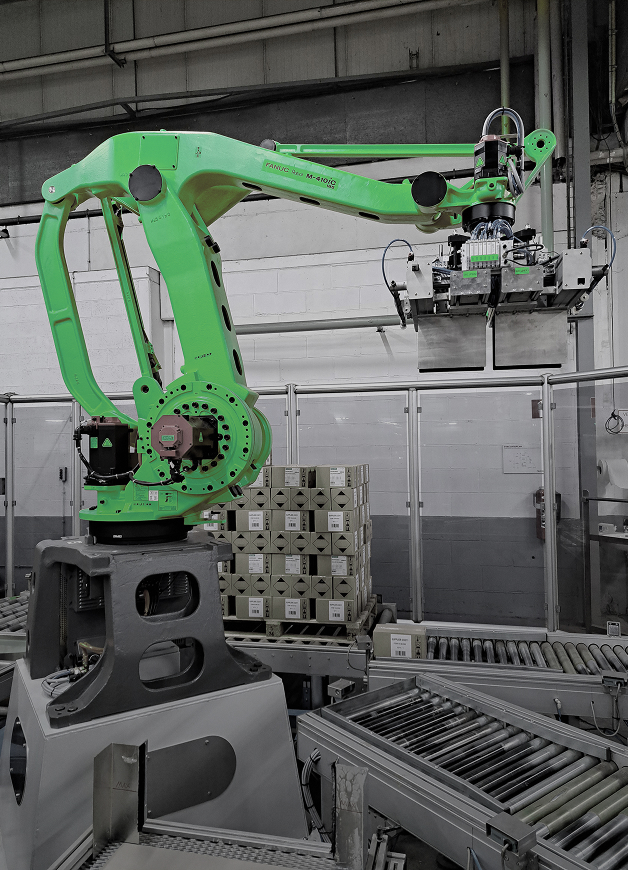

ASSEMBLY LINE FEEDING FOR AUTOMATED PROCESSES: ABSOLUTE PRECISION.

Dymation's solutions

Unlock the potential of production line feeding.

FROM CONSULTING TO TECHNOLOGY

Turn your weaknesses into strengths by choosing automation for your production line feeding process.

We design advanced line feeding solutions using flexible automation systems. The goal is to optimise productivity, reduce costs and improve operator safety. Using innovative technologies and a modular approach, our solutions can be customised to your specific needs, ensuring seamless integration with existing processes. How do we do that?

Find out more about Dymation's solutions

Keep your competitiveness in line.

For every line feeding automation project, we identify areas of improvement and then design customised systems, combining HW and SW to deliver tangible and measurable value.

- Assembly optimisation

- Waste reduction

- Enhanced safety

- Integration with existing technologies

- Dedicated expert team

Dymation turns potential into competitiveness.

Change becomes efficiency.

Tomorrow becomes today.

This is innovation, with Dymation.