LOG IN-EKANBAN

THE MOST ADVANCED SOLUTION FOR ASSEMBLY LINE MANAGEMENT USING A DIGITAL KANBAN.

THE FUTURE OF PRODUCTION LOGISTICS

Getting to the heart of production process digitisation to enhance efficiency and productivity. That’s what we do. What we’ve always done. With experience, specialised skills and proven results.

WHAT IS LOG IN-EKANBAN

This LOG iN module is designed according to the eKanban principle: simplify in order to optimise.

It is an industry benchmark, driving intralogistics evolution and offering digital solutions to transform materials management. LOG iN-eKanban is the result of Dymation’s extensive experience: a state-of-the-art electronic system designed to optimise the flow of materials while improving assembly line feeding operations. With our experience and know-how, you can rely on us to transform your production with innovative digital solutions.

LOG iN-eKanban, excellence for lean production.

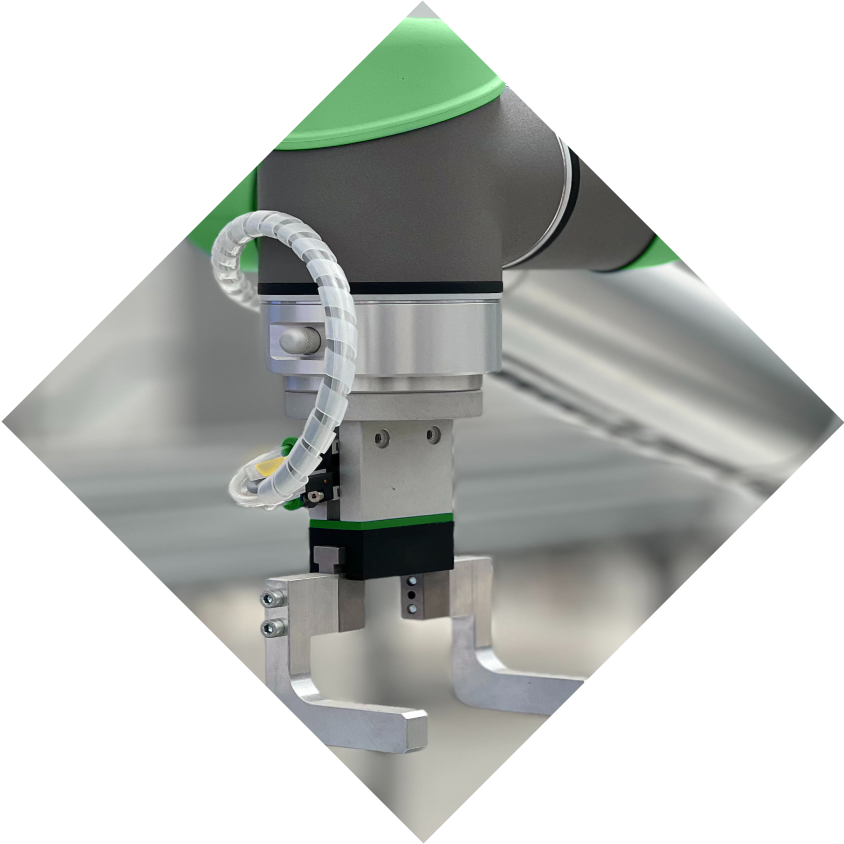

LOG iN-eKanban is the digital evolution of our Lean Logistics approach, in that it is designed to eliminate inefficiencies through the implementation of the lean philosophy in assembly processes. By automating material flow, this digital solution reduces operators’ manual tasks and improves synchronisation between different production stages, ensuring a streamlined and seamless value chain.

Eliminating bottlenecks

Optimised inventory management

Responsiveness to changes in demand

Enhancing human labour

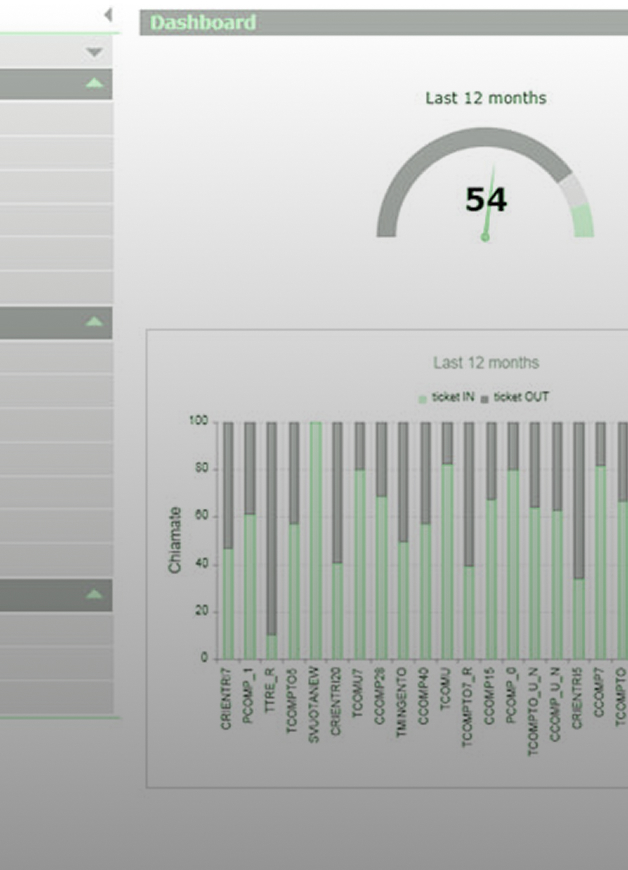

Total traceability and strategic analysis

Reduced lead time

Promoting continuous improvement (Kaizen)

Handling Efficiency and Improved Safety

FIND OUT MORE ABOUT LOG IN-EKANBAN

The digital solution to boost your assembly line precision.

LOG iN-eKanban is customised to your specific plant needs. We train operators to ensure optimal use of the solution. We provide regular maintenance, upgrades, and dedicated non-stop support.

- Reduction of excess inventories

- Material handling optimisation

- Operational flexibility

- Enhancing human labour

- Supporting improvement culture

LOG iN is more than eKanban: it is a comprehensive family of digital applications designed to control plant processes. Each module is designed to address specific needs, providing concrete and integrated support to Dymation’s process and automation consulting service.