LOG IN-MAINTENANCE

THE ULTIMATE SOLUTION FOR INTEGRATED INDUSTRIAL PRODUCTION MANAGEMENT.

TOTAL CONTROL AND MAXIMISED PRODUCTIVITY

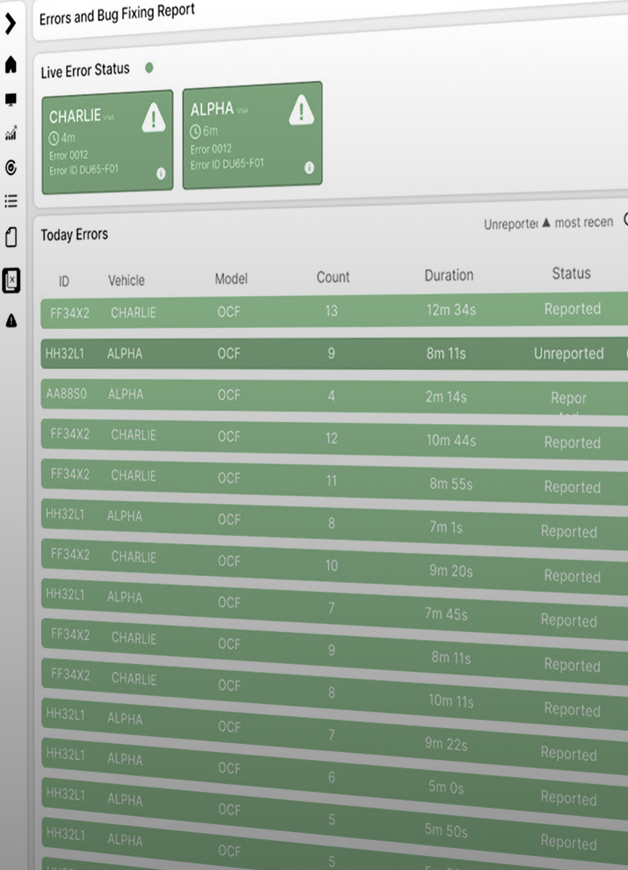

Solving problems before they arise. We provide a comprehensive overview of your machinery, helping you make effective and targeted choices.

WHAT IS LOG IN-MAINTENANCE

This LOG iN module is designed to digitise maintenance and boost production efficiency.

Our innovative digital solutions have revolutionised production management. LOG iN-Maintenance is the advanced system that transforms the planning, monitoring and optimisation of production processes, ensuring efficiency and competitiveness. This LOG iN suite module is dedicated to integrated production control and digitisation. An intelligent platform ensuring maximum efficiency and operational responsiveness. Custom designed for your business. LOG iN-Maintenance goes beyond mere management: it redefines modern production paradigms, integrating Lean Manufacturing strategies and advanced automation.

Lean maintenance at its best.

LOG iN-Maintenance is the digital evolution of our Lean Logistics approach, designed to deal with maintenance proactively. The aim is to minimise obsolescence-related risks with intelligent maintenance planning, thus optimising machine performance and reliability over time.

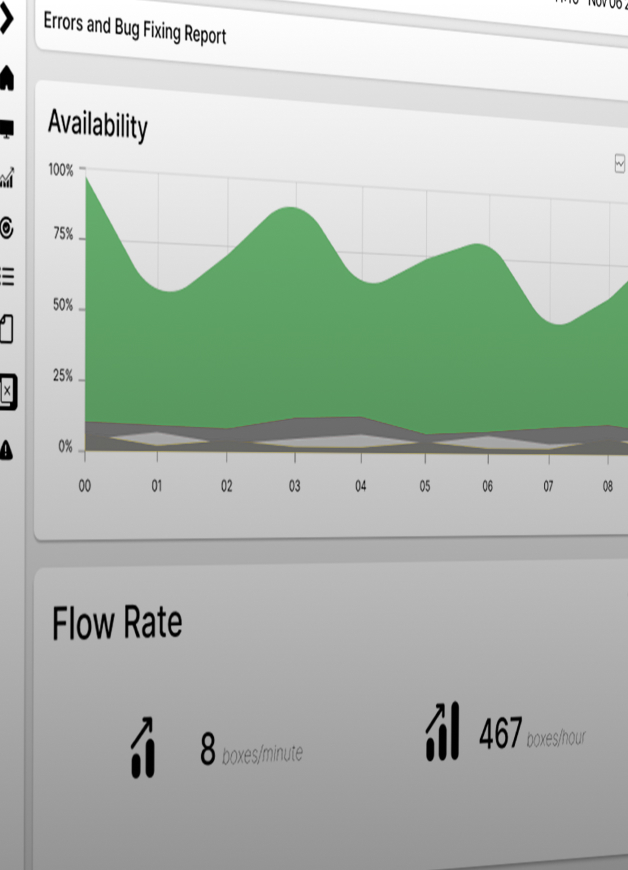

Elimination of operational waste

Efficient and proactive planning

Reducing energy waste

Real-time status analysis

Flexibility and adaptability

Enhanced Safety

FIND OUT MORE ABOUT LOG IN-MAINTENANCE

A powerful digital solution

for the future of your machinery.

LOG iN-Maintenance is customised to your specific plant needs. We train operators to ensure optimal use of the solution. We provide regular maintenance, upgrades, and dedicated non-stop support.

- Efficient planning

- Data-driven interventions

- Extended machine life-cycle

- Reduction of failure costs

- Enhanced safety

LOG iN is more than Maintenance: it is a comprehensive family of digital applications designed to govern plant processes. Each module is designed to address specific needs, providing concrete and integrated support to Dymation’s process and automation consulting service.