LOG IN-MOM

WHERE EFFICIENCY MAKES THE DIFFERENCE.

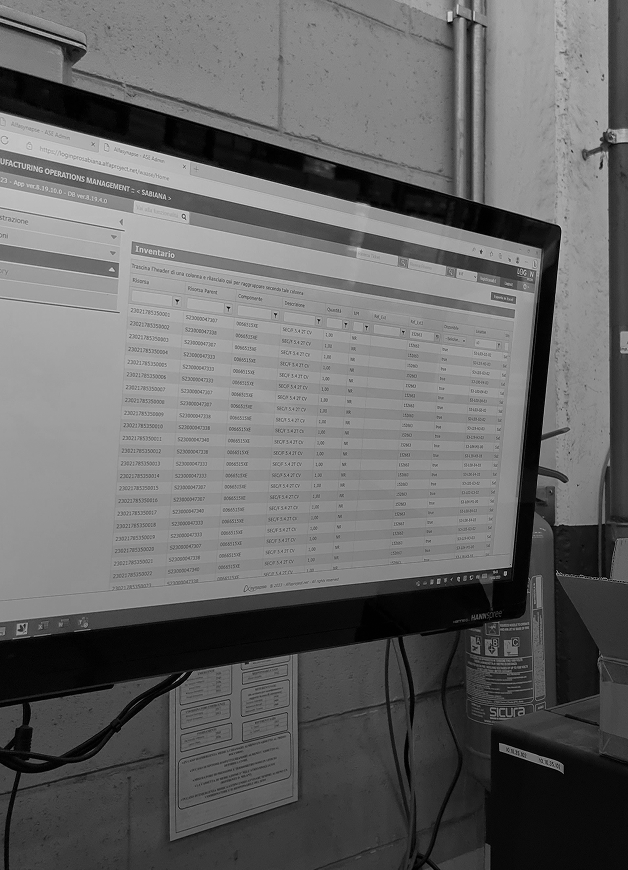

MANUFACTURING OPERATIONS MANAGEMENT

Planning activities, tracking movements, governing complexities, and increasing productivity with a thoroughly customised system.

WHAT IS LOG IN-MOM

The LOG iN module is designed for the digital and integrated management of your production.

LOG iN-MOM is the result of Dymation’s experience in the digitisation and optimisation of production processes. This LOG iN suite module provides real-time control and greater operational efficiency of the production line. This software is the synthesis of a high level of expertise and specialisation, and a benchmark in the intralogistics solutions industry. With LOG iN-MOM, clients have access to:

Rely on Dymation’s experience for smooth, accurate, and lean production.

LOG iN-MOM is the digital evolution of our Lean Logistics approach, making it possible to orchestrate production operations by integrating automation technologies and Lean Manufacturing strategies.

Preventive Maintenance

Continuous Improvement

Waste Reduction

Cycle Time Optimisation

Traceability and quality

Pull system

FIND OUT MORE ABOUT LOG IN-MOM

A powerful digital solution for your production management.

LOG iN-MOM is customised to your specific production line. We train operators to ensure optimal use of the solution. We provide regular maintenance, upgrades, and dedicated non-stop support.

- Advanced production management

- Monitoring and optimisation

- Data insights for better decisions

- Quality compliance monitoring

- Flow streamlining

LOG iN is more than MOM: it is a comprehensive family of digital applications designed to govern plant processes. Each module is designed to address specific needs, providing concrete and integrated support to Dymation’s process and automation consulting service.