DYMATION FOR THE PLASTICS INDUSTRY

PLANT AUTOMATION IN THE PLASTICS INDUSTRY: TAKE YOUR PRODUCTIVITY AND COMPETITIVENESS TO THE NEXT LEVEL.

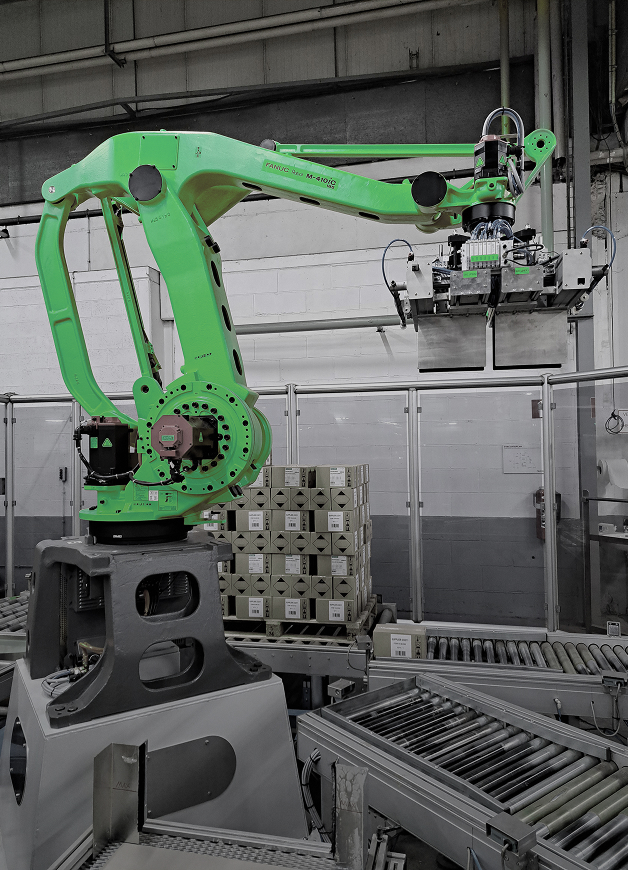

Customised automation solutions

Integrating industrial automation for plastics into your intralogistics is the key to innovation. Customised means exclusive.

Choose plant automation for plastics to streamline processes and boost competitiveness.

We design advanced solutions for plant automation in the plastics industry, optimising production processes while improving quality and operational efficiency. Improve your processes by using robotic technologies and integrated systems designed especially for your needs. Meet the challenges of an ever-changing industry with Dymation.

Why choose Dymation’s industrial automation for plastics?

Because we are experts as well as technicians, and we can support you in making the best choice based on your data. First, we identify the strengths and weaknesses, highlighting areas of improvement and simulating the impact of change on your production performance. Finally, we will clarify the investment by indicating the costs and benefits. It will be a fully-customised path involving integrated and scalable solutions. What can Dymation do for you?

Reduce operating costs

Increase productivity

Achieve greater operational flexibility

Optimise space

Minimise waste

Make work safer

Monitor trends in real time

Dymation for the plastics industry

Precision and efficiency to boost your production performance.

Optimisation bordering on perfection for each step of production. Reduce space, time, and cost by integrating technology into your processes. By implementing plant automation for plastics, all you have to do is… grow your business!

- Smart handling solutions

- Integration with other technologies

- Real-time control

- Enhanced safety

- Dedicated expert team

We design plant automation solutions for the following industries in the plastics sector.

Our automated plant solutions for the plastics sector are ideal and beneficial for production and logistics lines in a number of industries. Each system is designed to meet specific needs, providing tailored automation solutions that are perfectly in line with the process and automation consulting service offered by Dymation.

Dymation turns potential into competitiveness.

Change becomes efficiency.

Tomorrow becomes today.

This is innovation, with Dymation.