THE LEAN APPROACH

STREAMLINING PROCESSES TO INCREASE EFFICIENTY

A transformative philosophy

Implementing a LEAN Solution Factory to identify technological and innovative solutions, turning a challenge – the need for efficiency and cost containment – into new business opportunities.

ONE-TO-ONE PLANNING

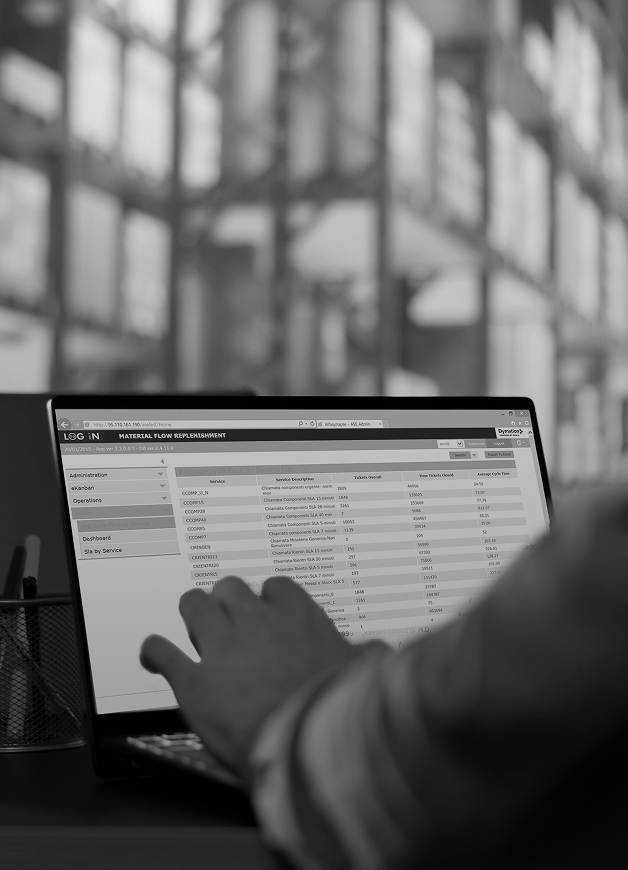

A methodological and engineering approach to support technology projects.

We use a LEAN approach to identify MUDA (non-value-adding activities) within industrial operating processes and map potential areas for improvement. We can thus identify the best digital and automation solutions to streamline plant operations and reduce waste.

We identify the 7 MUDAs. We eliminate them. This is Dymation.

The MUDAs (Japanese word for “waste”) represent the seven main factors creating inefficiency in business processes according to the Lean approach. Identifying and eliminating them from the client’s work chain is essential to improving their business processes and maximising productivity. This also enables us to spot weaknesses that can be addressed and corrected using automation solutions. Here are the seven MUDAs:

Overproduction

Waiting

Transportation

Over-processing

Inventory

Motion

Defects

DYMATION FOR YOUR BUSINESS

LEAN approach – for enhanced intralogistics efficiency

Rely on a multidisciplinary team to identify the best technology and automation solution for enhanced intralogistics efficiency, whilst triggering continuous improvement (KAIZEN).

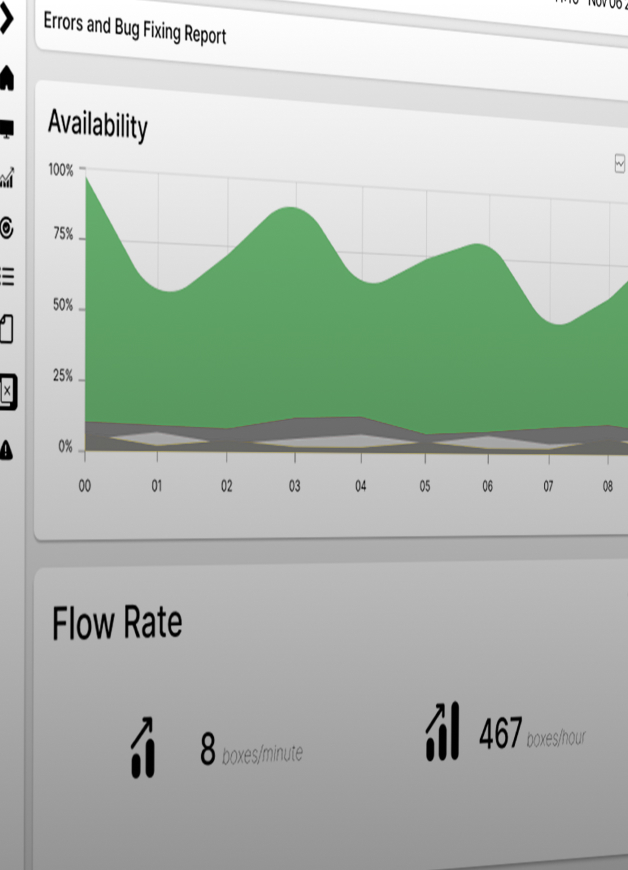

- Analysis of waste

- Process streamlining

- Customised consulting

- Global optimisation

- Dedicated technical team

WHO CHOOSES DYMATION

Our solutions are ideal and beneficial for production and logistics lines in many industries. Each system is designed to meet specific needs, providing tailored automation solutions that are perfectly in line with the process and automation consulting service offered by Dymation.